Wastewater is a complex variable mixture of waste materials in aqueous suspension/solution resultant from domestic and industrial activities, mixed with varying amounts of ground and surface water. It is described using its physical characteristics (e.g. colour, smell, debris), chemical characteristics (e.g. BOD, suspended solids, ammonia, phosphorus) and strength (e.g. septicity).

Sewage works are sampled so the works performance can be monitored and to ensure parameters are within legally consented values. Sample data can be used to identify early warnings of problems and can confirm if the site is adequately loaded, under loaded or overloaded.

On site testing can consist of: clarity (to see how clear the final effluent discharge is and to get information on suspended solids), ammonia, settlement volume, temperature (treatment is not as efficient in lower temperatures) and sludge depths of tanks (to ensure a compact sludge blanket with minimum suspended solids). Lab tests can include: BOD, COD, suspended solids, ammonia, phosphorus and metals such as iron and aluminium.

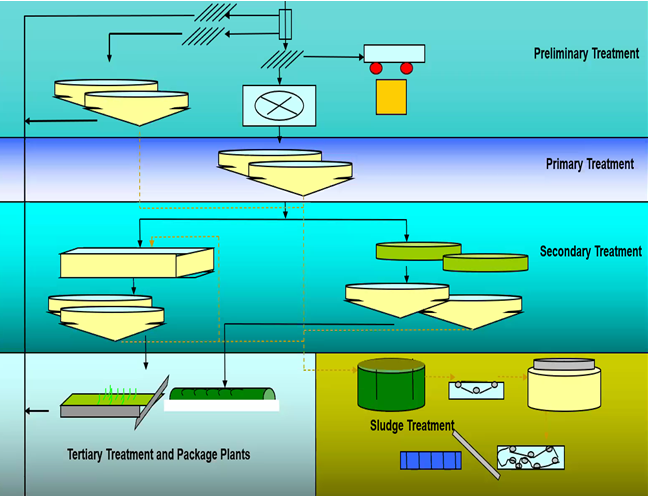

Wastewater treatment occurs in 5 stages: preliminary, primary, secondary, tertiary and sludge.

The main reduction in pollutants such as ammonia and BOD occur through biological treatment in the secondary treatment step. Other pollutants including suspended solids and phosphorus are removed by mechanic and/or chemical methods.

|

| Overview of Treatment - Wessex Water |

Preliminary Treatment

Preliminary treatment consists of storm separation, a screening process, grit removal and a compactor system.

FFT (flow to full treatment) is the maximum rate of flow that a sewage treatment works can treat before the storm flow system goes into operation. During heavy rain, the flows to a sewage works increase, moving closer to the FFT. When flows exceed the FFT, the flow enters the storm system, normally a series of storm tanks used for storage and settling. When these storage tanks are also filled up, the flow (which by this point is very dilute) enters the surface water, such as surrounding rivers.

The screening process can consist of a few different technologies to remove RAG, fibrous material that does not break down after being flushed down the toilet.

|

| Rotating Rake - Wessex Water |

The image depicts a rotating rake. In this process, RAG scrapes up the red line (in the left image) and into a trough. A 6 mm mesh blocks the solids. When solids build up at the bottom, higher up the mesh is used instead (like the zombies going over the wall in World War Z!). When the solids build up so far, a wash is triggered to clean the mesh from blinding. During the wash, the screen rotates and the brush will clean any solids and send them to a compactor system.

|

| Paramount Pictures |

The compactor system looks like a screw. The system dewaters and compresses waste, with liquid being drained through the lower part of the compactor.

|

| Compactor System - EvoTech |

There are various different types of grit removal. Grit removal is the process used to remove sand, silt and grit from water.

Primary Treatment

Primary treatment is a physical phase separation used to remove settleable solids. It normally consists of primary settlement tanks, which settle out solids, in a way similar to storm tanks. The inlet enters through the bottom of the tank, then the flow radiates outwards. Often there is a rotating scraper which scrapes sludge into a hopper.

|

| Primary Treatment - Wessex Water |

|

| Primary Settlement Tank |

Secondary Treatment

Secondary treatment is the removal of biodegradable organic matter using biological processes. In this treatment stage, microorganisms digest sewage in a managed aerobic or anaerobic process depending on the treatment technology, using either a fixed-film or suspended-growth system.

Biofilm grown on a fixed media:

- Biological Trickling Filter

- Submerged Aerated Filter (SAF)

- Biological Aerated Flooded Filter (BAFF)

- Rotating Biological Contactor (RBC)

- Submerged Biological Contactor (SBC)

- BioClere Package Plants

- High Rate Filter (HRF)

Suspended biofilm media:

- Activated Sludge Plants (ASP)

- UNOX

- Sequence Batch Reactor (SBR)

- Oxidation Ditch

Helpful microorganisms in biological processes which aid settling include: crawling ciliates, free swimming ciliates, rotifers and stalked ciliates. Undesirable microorganisms can consist of: filamentous bacteria, amoeba and nematode worms.

Settlement volume (SV) is a way to see how healthy sewage is and how well it settles. If it does not settle well, it is likely there are filamentous bacteria, if it does not, there is not likely microorganisms present that are good for treatment.

Biological Trickling Filters are often seen at UK wastewater treatment works. There are nozzles in the rotation arms. Sewage goes through the nozzles which drives the filter around, meaning no power is needed. This sewage then percolates through a filter to under drain channels.

There is ~2m deep biomass growth on the surface of the media which needs food (sewage), a moist home (the media surface) and oxygen to respire (obtained through air vents). At the top of this biomass there is BOD bacteria, nitrifying bacteria growth in the middle and ammonia treatment happens at bottom.

|

| Trickling Filter - Water Action Plan |

ASP are another treatment technology often seen at UK wastewater treatment works. Sewage enters, is mixed with microorganisms in the selector zone and passes through aerated lanes. These lanes have a certain retention time to give bacteria time to digest the sewage.

|

| Suspended Growth Porcesses: Wessex Water |

|

| BAFF |

Final settlement tanks (FSTs) are similar in design to primary settlement tanks and are an integral part of the activated sludge process.

Tertiary Treatment

Tertiary Treatment is used for consents (e.g. suspended solids, BOD, ammonia) and nutrient removal (e.g. phosphorus, iron, aluminium). Examples of treatment processes can include: sand filter, mixed media filter, cloth filter, UV, lagoons, microscreens, reed beds and grassplots.

Sludge

Secondary treatment processes can get a solids build up, a surplus of activated sludge (SAS). Some of this activated sludge goes to waste at a sludge treatment centre.

Solids are collected in primary and final settlement tanks. This is dewatered and then tankered to a sludge treatment centre. The dewatering is helpful to reduce the number of tankers.